FIBRE OPTICS REDEFINED

Cleerline’s proprietary SSF™ technology sets a new standard in fibre optic performance, durability, and ease of use. Our solutions are designed to meet the demands of today’s fast-paced, data-driven world. With up to 200 times the durability and 10,000 times the bend longevity of traditional fibres, SSF™ technology ensures reliable connectivity even in the most challenging environments. Whether you’re building a data centre, upgrading your network infrastructure, or installing home theatre systems, Cleerline’s SSF™ solutions deliver unmatched performance and peace of mind.

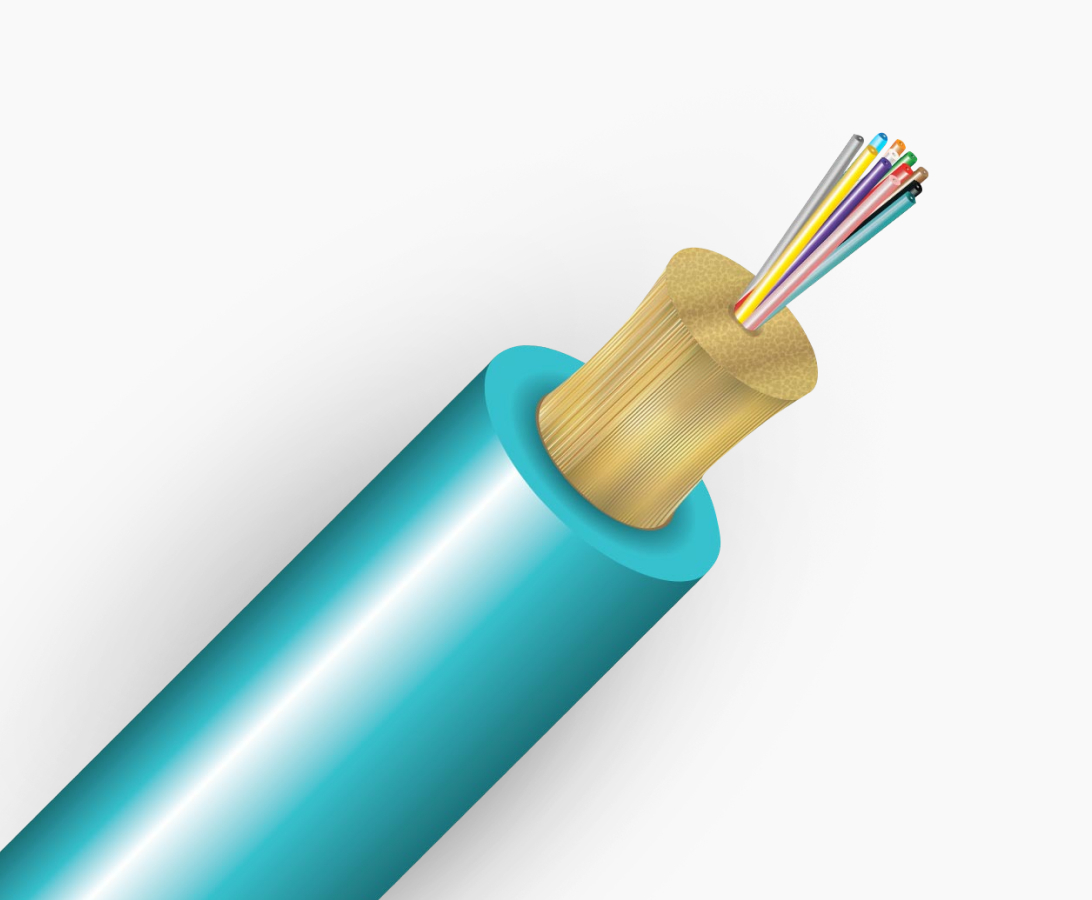

Advanced SSF™ Technology

Our patented Glass, Glass, Polymer (GGP) fibre construction offers unparalleled strength and flexibility.

Faster Termination

SSF™ fibres are quicker and simpler to terminate, reducing installation time and costs.

Enhanced Safety

The unique coating of SSF™ fibres minimizes the risk of skin punctures during handling.

Comprehensive Solutions

Cleerline offers a wide range of fibre optic products to meet diverse connectivity needs.

Cleerline's Product Lineup

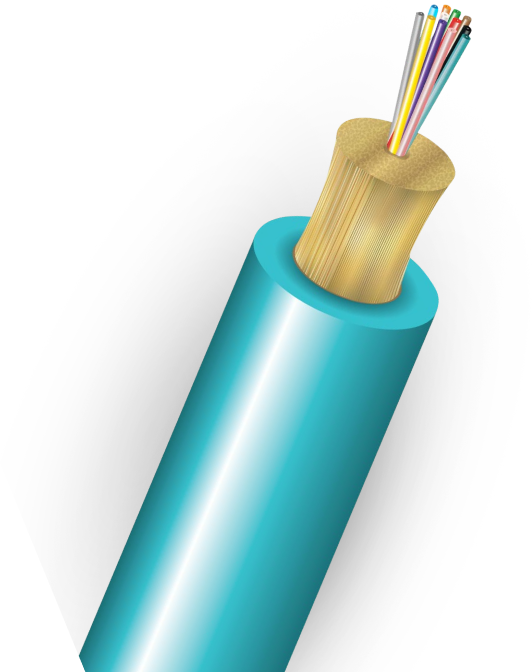

SSF - Bulk Cables

Cleerline's SSF™ bulk cables are available in various fibre types (OS2, OM2, OM3, OM4) and jacket options (Riser, Plenum, LSZH) to suit your specific requirements. These cables offer superior strength, durability, and bend performance compared to traditional fibre optic cables.

View Full RangeTools & Kits

Cleerline offers a comprehensive range of specialised tools and kits designed to streamline fiber optic installations and terminations. Each tool and kit is carefully curated to complement Cleerline's SSF™ technology, ensuring that installers can fully leverage the benefits of our stronger, safer, and faster-to-terminate fiber optic solutions.

Connectors

Cleerline's SSF™ field-installable LC & SC type connectors eliminate the need for hand polishing, epoxying, or crimping. Our exclusive hinge-based design and large verification windows ensure precise fibre alignment and low-loss terminations.

View Full RangeAccessories

Complete your fibre optic setup with Cleerline's range of accessories, including adapters, attenuators, and patch cords. Our accessories are compatible with industry-standard connectors and designed to deliver optimal performance.

Connect With Our Experts Today

Cleerline SSF™ fibre optic solutions are redefining the industry with unmatched strength, durability, and performance. Interested in learning more? Contact our team today for exclusive pricing, expert guidance, and irresistible discounts.

Keep An Eye On The Latest Offers!

Stay ahead with our newsletter. Sign up to receive updates, exclusive offers, and insights straight to your inbox.